Semiconductor and solar cell business

Laminator

> Semiconductor and solar cell business > PV module Manufaturing Equipment for High Electrical Saving > Laminator

> Semiconductor and solar cell business > PV module Manufaturing Equipment for High Electrical Saving > LaminatorEquipment overview

Photovoltaic modules are generally manufactured through Tabbing & Stringing and Lay-up and Lamining and Triggering, Framing and J/B Assembly and Simulating.

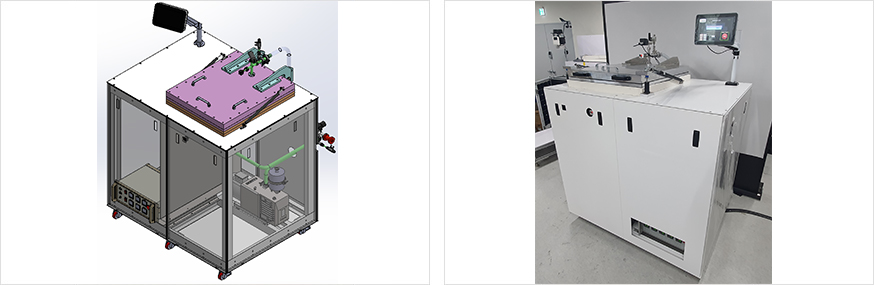

This equipment is energy-saving solar module process equipment with high productivity PCM. By integrating the Tab & String process and the Lamination process the manufacturing equipment area and energy and curling time can be reduced in the lamination process using high-efficiency ceramic heaters and phase conversion materials (PCM). and the Tab & String process and lamination process can be performed simultaneously to reduce the manufacturing process and improve the price competitiveness of the Solar module.

Image